The Hydrogen Race Is On – But Will Water Infrastructure Keep Pace?

With hydrogen demand forecast to quadruple by 2050, the global transition to green hydrogen water treatment is now in full swing. In the UK, the Government’s Hydrogen Allocation Round 2 (HAR2) process shortlisted 27 electrolytic hydrogen projects across England, Scotland, and Wales in April 2025. These projects are now advancing through due diligence and cost challenge reviews, with contract awards expected later in 2025. As developers refine their commercial propositions, pressure is mounting to demonstrate deliverability, efficiency, and long-term value.

While the immediate opportunity is HAR2 hydrogen UK, the UK Government has confirmed annual hydrogen allocation rounds will continue through to at least 2030, with HAR3 hydrogen expected to open by early 2026. This article explores how the right green hydrogen water treatment strategy can support project success, including key applications such as electrolyser feed water, fuel cell production, and hydrogen cooling systems – not just under HAR2, but in shaping the UK’s broader hydrogen economy.

Why Ultrapure Water Is the Hidden Enabler of Electrolyser Performance

Despite hydrogen’s visibility in the energy transition, the role of water is often underplayed. Green hydrogen production via electrolysis depends entirely on high-purity water – making ultrapure water hydrogen systems an essential part of any electrolyser package.

Contaminants in feed water can shorten stack life, lower yield, increase downtime, and compromise warranties. A robust hydrogen water purification approach isn’t a nice-to-have – it’s a fundamental enabler of performance, safety, and cost control. For a technical breakdown of membrane treatment options, see our Q&A article on water treatment technologies for hydrogen production.

From that perspective, water quality must be treated with the same strategic importance as power input, stack design, or site layout. Site layout is critical – consultants and contractors must get this right from day one to avoid costly redesigns and ensure progress on the critical path.

Water treatment considerations also support:

- Ensuring regulatory compliance – specialist water treatment solutions

- Identifying key utility requirements – seamless, cost-effective integration

- Sizing water treatment systems – reliable performance to meet decontamination demands

- Designing plant rooms – optimal building layout and system operation

- Specifying resilient systems – robust, long-term performance in critical applications

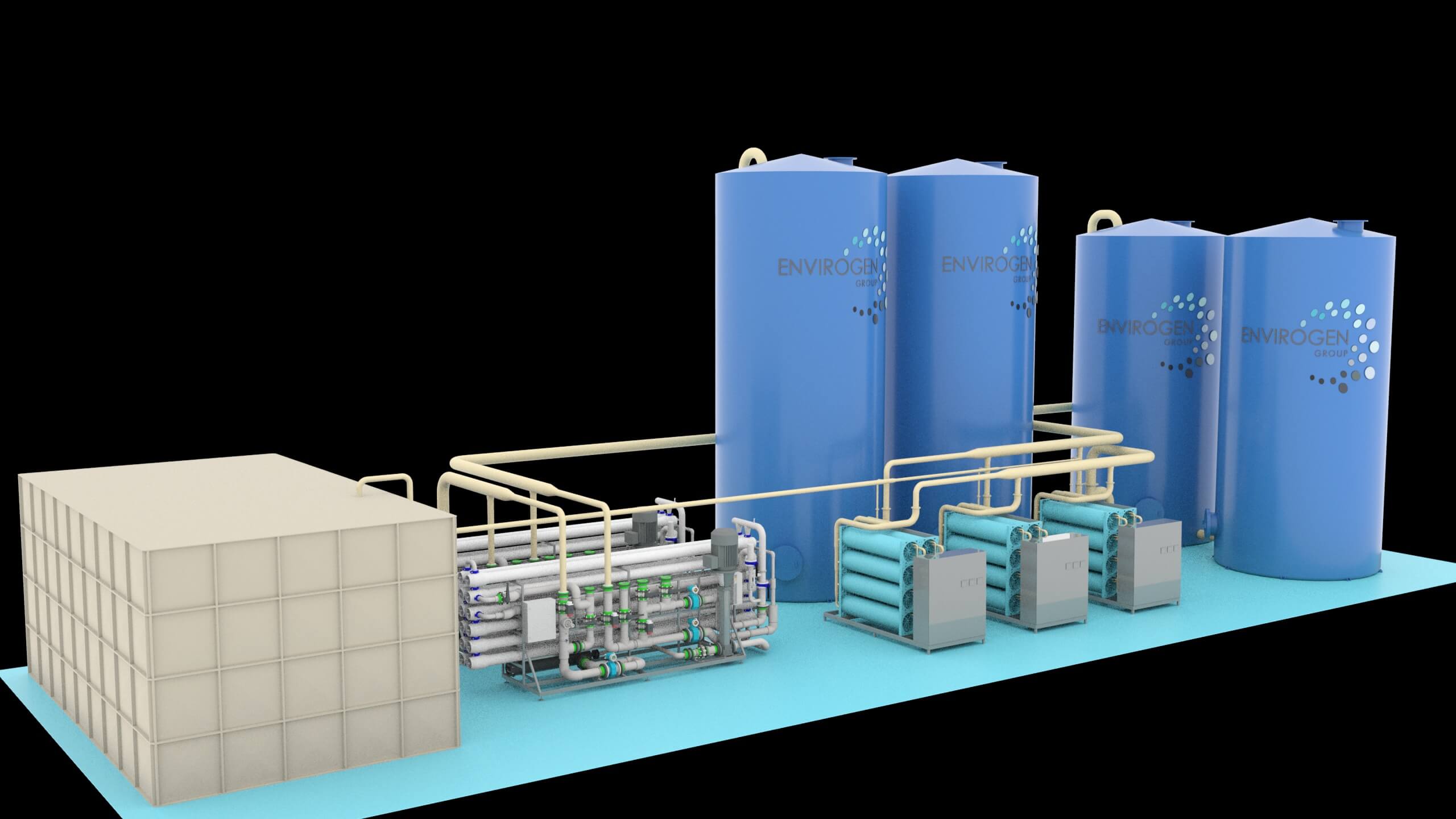

That’s why Envirogen’s hydrogen sector offering is built around high-reliability systems featuring reverse osmosis, electrodeionisation, and membrane filtration, designed to meet the uptime and quality demands of industrial-scale electrolysis.

An Envirogen Group water treatment system for hydrogen production.

HAR2 Priorities Demand More Than Just Clean Water – They Require Strategy

The HAR2 hydrogen UK process outlines four core evaluation priorities:

- Technical and commercial viability

- Cost-competitiveness

- Value-for-money delivery

- Support for UK industrial growth and resilience

Envirogen’s water treatment solutions directly support all four:

- Modular membrane-based systems enhance technical viability by simplifying integration and lowering technical risk.

- Our Life Cycle Costing (LCC) methodology and system guarantees improve cost-competitiveness.

- UK-built systems and engineered service packages deliver measurable value for money.

- Local design, build, and install capacity helps accelerate delivery and supports UK industrial growth.

We also offer early-stage technical guidance and compliance support, especially around site-specific water challenges. This reduces rework at later design phases and helps HAR2 project teams strengthen their delivery case.

Pilot plant trials are also available to support these efforts – enabling project teams to test technology on live process streams, generate performance data, model costs, and prove full-scale viability under real-world conditions.

H₂ HydroPro: One Skid, Three Technologies, Zero Regeneration Chemicals

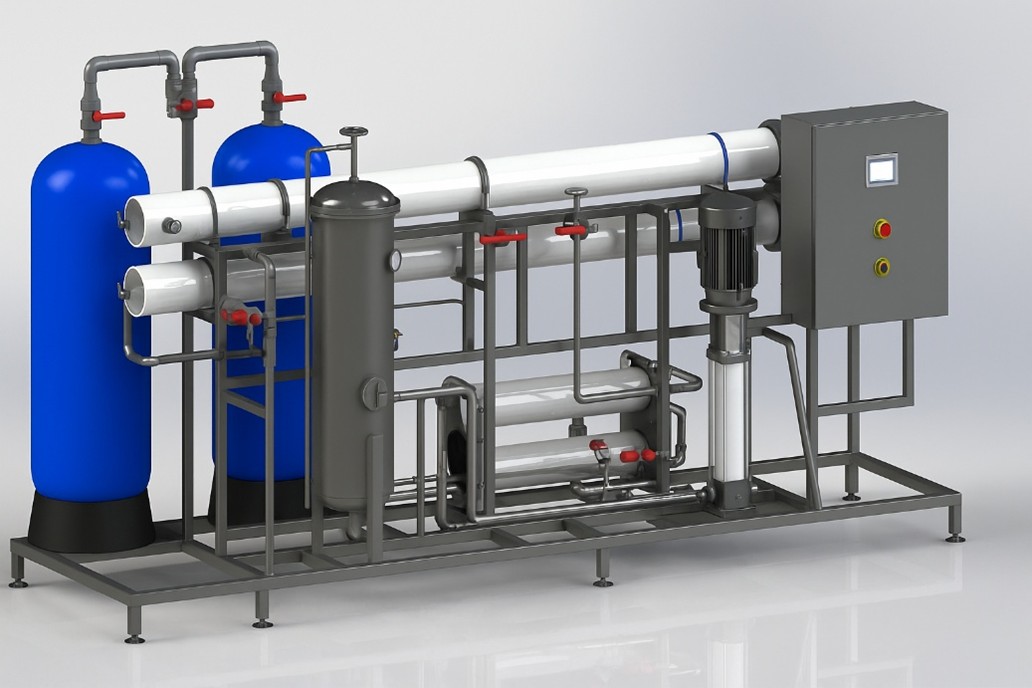

Envirogen’s H₂ HydroPro hydrogen water treatment system offers a fully integrated RO EDI skid hydrogen solution, well-suited to green hydrogen water treatment project teams seeking a simple, scalable ultrapure water setup.

The unit combines:

- Reverse osmosis (RO)– high-efficiency removal of dissolved salts

- Electrodeionisation (EDI) – polishing stage for ultrapure output

- Integrated pre-treatment – tailored to source water

Importantly, there’s no need for hazardous chemical regeneration. The plug-and-play design accelerates deployment and reduces HSE burden – ideal for new hydrogen projects and EPC-led rollouts.

Designed specifically for hydrogen applications, the system supports:

- Electrolyser feed water – providing ultrapure water essential for efficient, long-life stack operation

- Fuel cell production – meeting ultrapure water standards for manufacturing sensitive fuel cell components

- Hydrogen cooling systems – delivering high-purity water for safe and stable cooling in hydrogen production and storage

The H₂ HydroPro system is shown here in its standard skid-mounted layout, with containerised formats also available for outdoor installations. This all-in-one, multi-technology RO-EDI plant is designed to deliver high-purity water for hydrogen production.

Sustainability Without Compromise: Water Reuse and ZLD in Hydrogen Projects

Sustainability is fast becoming a strategic differentiator. With growing pressure on water resources, developers are increasingly evaluating zero liquid discharge hydrogen and hydrogen plant water purification strategies to reduce usage and discharge.

From a design perspective, our team supports:

- Water recycling for non-electrolyser applications (cooling, cleaning)

- High-recovery RO configurations

- Brine minimisation and reuse pathways

These solutions help projects meet broader ESG and permitting requirements – and align with the value-for-money and resilience goals set out in HAR2.

The Value of Early Partnering

Increasingly, consultant groups, engineering-integrator partners (EIPs), and EPC contractors are engaging early with specialist hydrogen water treatment companies UK to shape system design and utility requirements from day one. These partnerships align water system planning with broader site infrastructure, helping avoid costly redesigns and delays.

For more on how collaboration adds value across project stages, see our article on the importance of partnerships in industrial water treatment.

Plan Now for HAR3 – Or Risk Being Left Behind

Envirogen offers complimentary system assessments for shortlisted HAR2 projects and developers preparing for HAR3 hydrogen submissions. Whether you’re designing a pilot or scaling to commercial capacity, our team can help define the right green hydrogen water treatment solution.

As outlined in our Q&A article, we bring deep experience across:

- High-purity water for electrolysis and fuel cell manufacturing

- System modularity and build efficiency

- Water reuse and ZLD planning

- Integration with EPC procurement strategies

Looking for a supplier of green hydrogen water treatment systems? Envirogen supports projects across the UK with engineered solutions tailored for HAR2 and beyond.

Let’s build a system that works for today – and for 2050.

For a FREE, no-obligation assessment on how you can save energy, water, waste and money, contact our team of expert engineers