Kemira selected Envirogen following a competitive tender process to deliver a bespoke, containerised water treatment plant for its Bradford facility. The Eco MultiPro system went live in Q4 2025, providing essential ultrapure water to support Kemira’s updated flocculant manufacturing operations.

Aligning ultrapure water supply with manufacturing strategy

Kemira’s Bradford site manufactures polyacrylamide flocculants used globally across industries to improve water treatment efficiency. As part of a broader manufacturing upgrade, Kemira introduced a new production process that required a more reliable and higher-capacity source of ultrapure water than its existing ion exchange system could provide. The new setup had to support consistent process performance, meet stringent conductivity targets, and integrate smoothly into an operational facility.

Multi-technology RO-CDI water treatment

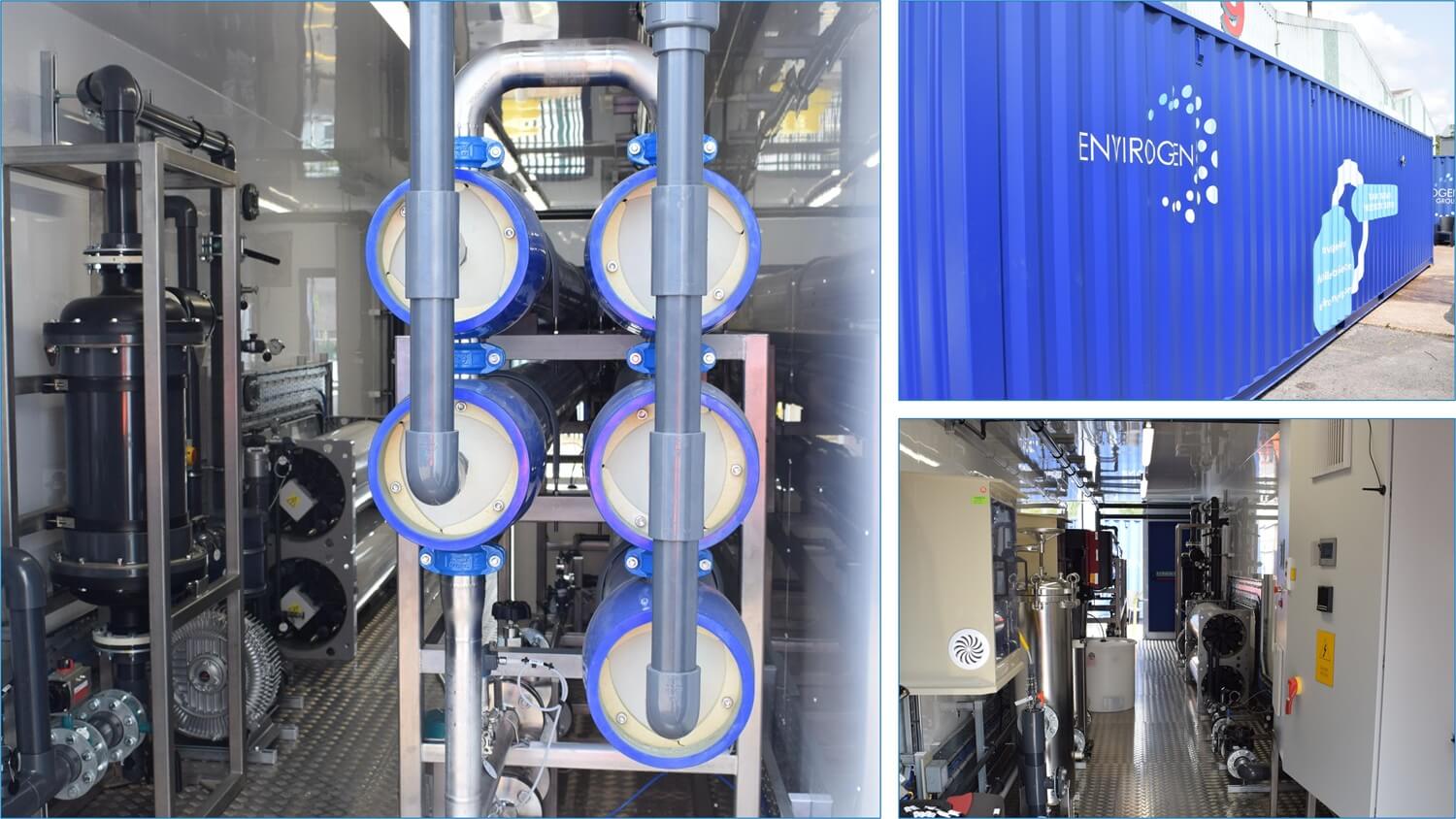

Envirogen designed and supplied a containerised Eco MultiPro water treatment system. Built around the MultiPro Reverse Osmosis–Continuous Deionisation (RO-CDI) platform, the solution combines reverse osmosis technology, a carbon dioxide degas membrane, and continuous electro-deionisation (CDI) in a compact, modular skid.

The three-stage, chemical-free treatment process consistently delivers ultrapure water with an outlet water quality of less than 0.5 Microsiemens per centimetre (μS/cm). The design removes the need for strong chemical handling, reducing health and safety risks, operational overhead, and environmental impact.

Envirogen Eco MultiPro RO-EDI Containerised-System

Project delivered on time with efficient integration

The Eco MultiPro system went live in Q4 2025. Envirogen managed the full scope of works, including design, build, commissioning, and project management. The system was delivered as a containerised, plug-and-play solution for ease of integration and installation within the operational constraints of the Bradford facility.

To protect the membranes and ensure long-term system performance, pre-treatment includes 5-micron cartridge filtration and dosing for hardness and chlorine control. Reverse osmosis removes 96-98% of total dissolved solids (TDS), while the downstream CDI stage polishes the water further to achieve final conductivity levels aligned to Kemira’s specifications.

System monitoring and control is enabled via a PLC and touchscreen HMI, with PureCare remote monitoring functionality providing off-site visibility and support for efficient performance management.

Supports yield, efficiency and operational performance

The Eco MultiPro system now forms a critical part of Kemira’s manufacturing infrastructure. It supports stable yield, consistent product quality, and reduced operational risk across Kemira’s upgraded flocculant production line.

Graham Scarborough, Plant Manager, Kemira Bradford:

“High-quality, ultrapure water is strategically important and fundamental to our manufacturing process. Because it helps to ensure product consistency, process efficiency and long-term performance, it was crucial that we partnered with the most appropriate supplier for our particular needs.”

Ben Phillips, Regional Sales Manager, Envirogen:

“The Eco MultiPro meets Kemira’s objectives of providing a treated water flow rate of 25 cubic metres per hour, with an outlet water quality of less than 0.5 μS/cm. The system aligns with their goals around operational reliability, safety, and long-term sustainability.”

Key outcomes

- Containerised ultrapure water system operational at Kemira Bradford

- Treated water flow rate of 25 m³/hr at <0.5 μS/cm conductivity

- Three-stage RO-CDI process with carbon dioxide degas membrane

- Reduced chemical handling and safety risk

- Remote monitoring for efficient performance oversight

- Delivered as a plug-and-play modular package

Contact us for more information on the benefits of water softener systems for your business

About the client

Kemira is a global leader in sustainable chemical solutions for water-intensive industries. Its polyacrylamide flocculants are used worldwide to improve water treatment efficiency and reduce pollution in industrial and municipal systems.