For more than a century, pressure leaf filters have provided an economic, reliable and proven cake filtration solution for liquids with higher solid loads, between 0.01% – 3%. These highly effective systems consist of pressure vessels containing individual ‘filter leaves’ supported on a manifold.

Liquid is pumped into the pressure leaf filter vessel where it is pushed through the filter leaves, exiting the vessel via the manifold. Solids are retained and form a filter cake on the leaves. When filtration is complete, the filter is drained, leaving the cake on the filter leaves. Depending on the application, the cake can then be sluiced off the leaves or dried and then discharged by a pneumatic vibrator.

Our range of Envi Leaf pressure leaf filters are perfect for both dry and wet cake discharge, in both vertical and horizontal vessel orientations. We provide a range of filter meshes for every filtration step in edible oil production, gelatine processing, liquid sulphur filtration and bio-diesel production. Our top-gauze filter leaves, such as our PZ80, 60 mesh, 24×110 Dutch weave, are ideal for these high-demand industries and are constructed from 316L or 904L stainless steel.

Typical markets and applications include:

- Edible oil processing (crude oil, bleached oil, winterised oil)

- Gelatine processing

- Pectin processing

- Glucose, sweeteners, sugar, fruit juice production

- Bio-diesel production (pre-treatment and polishing)

- Liquid sulphur filtration

- Chemicals and oleochemicals

- Organic and inorganic salts, amines, resins and bulk drugs

Pressure leaf filter solutions for dry or wet cake discharge

Our range of Envi Leaf pressure leaf filters are designed and engineered using the latest technology to greatly improve cake discharge properties. Envi Leaf long-lasting filter elements require less maintenance and fewer changeovers and repairs, which leads to reduced operational costs, increased productivity and higher filtration efficiency.

Vertical pressure leaf filter

This economical pressure leaf filter is equipped with vertical, rectangular filter leaves. The filter leaves are mounted vertically and connected to a filtrate manifold at the bottom of the filter tank. For dry cake discharge, a vibrator is used to remove the cake from the filter leaves when the filtration process is complete.

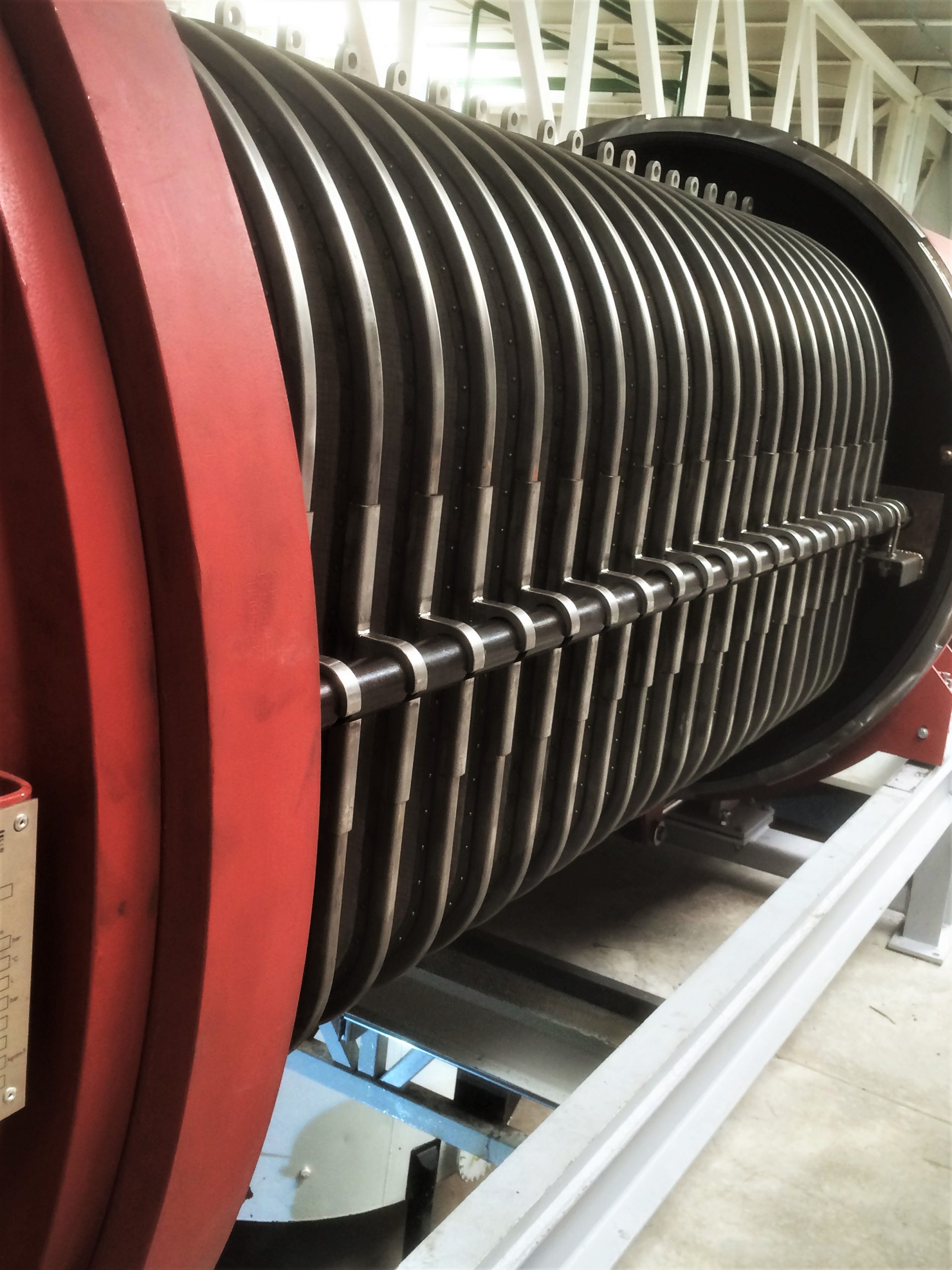

Horizontal pressure leaf filter

Horizontal pressure leaf filters contain filter leaves positioned vertically in a horizontal filter tank. These filters can have a large filtration area and enable visual cake inspection after every cake discharge. An optional vibrator installation can be installed for cake discharge.

Envi Leaf pressure leaf filters deliver:

- Space-saving, compact design – these compact systems achieve high flow rates and operate at pressures of up to four bars.

- Long-life filter leaves and filter mesh – constructed from five layers (ply) of stainless-steel wire mesh, each internal filter leaf is designed for long-life. Reduced maintenance requirements mean a low total cost of ownership and each leaf offers years of service.

- High-efficiency – with excellent pre-coating properties.

- Adaptability – Envi Leaf pressure leaf filters can be sized according to your application – with vertical vessels ranging from 5m² to 125m².

- Multi-purpose – one system can be used at multiple stages in the filtration process, customised by the mesh and the structure of the filter leaves within.

- Quicker discharge – our air vibration system ensures quick and easy cake discharge. With fast drying processes, we ensure the minimum amount of liquid wastage during cleaning cycles.

- Enhanced robust design – our enhanced nozzle has a unique u-shaped profile and is enclosed within a manifold. This design creates a strong bond with the tank, delivers a smooth flow and prevents damage during cleaning.

- Safe operating – the completely closed filter body ensures safe operating conditions at high temperature.

Order pressure leaf filter spare parts with our flexible stocking programme

A safe and secure supply of spare parts and replacements is an essential part of any manufacturing operation. With our flexible stocking programmes and technical expertise and advice, we’ll ensure delivery of spare parts and replacements when you need them, minimising interruption to your production cycle. We will work with you to develop a stocking system to meet your needs. Spare parts for pressure leaf filters can be held on your site or we can provide immediate dispatch from our warehouses for fast delivery.

Tailored filtration solutions to meet your needs

Selecting the right pressure leaf filter technology for your application will depend on many factors like the flow rate, continuous or batch processing, the type and amount of solid load, the nature of the liquid, the temperature and the liquid viscosity.

Our team of process experts recommend solutions to maximise the effectiveness of your filtration process, enabling you to hit production and quality targets with a low total cost of ownership