Turning challenging sources into safe, potable supply, with surface water nanofiltration

Surface water nanofiltration is transforming how rivers, lakes, and reservoirs are treated for drinking water. These raw water sources often have high turbidity, seasonal variation, organic matter, colour, pesticides, and emerging contaminants that affect quality and reliability.

SurfacePure is Envirogen’s specialised direct nanofiltration (dNF) system for surface water treatment. Using advanced surface water treatment membranes, SurfacePure removes key contaminants while retaining essential minerals, delivering safe, compliant, and high-quality drinking water.

For added assurance, pilot-scale validation and water testing can be carried out to confirm system performance before full installation, and Envirogen can provide a free site survey to ensure the right system fit from the outset.

Direct nanofiltration (dNF) hollow fiber membrane technology

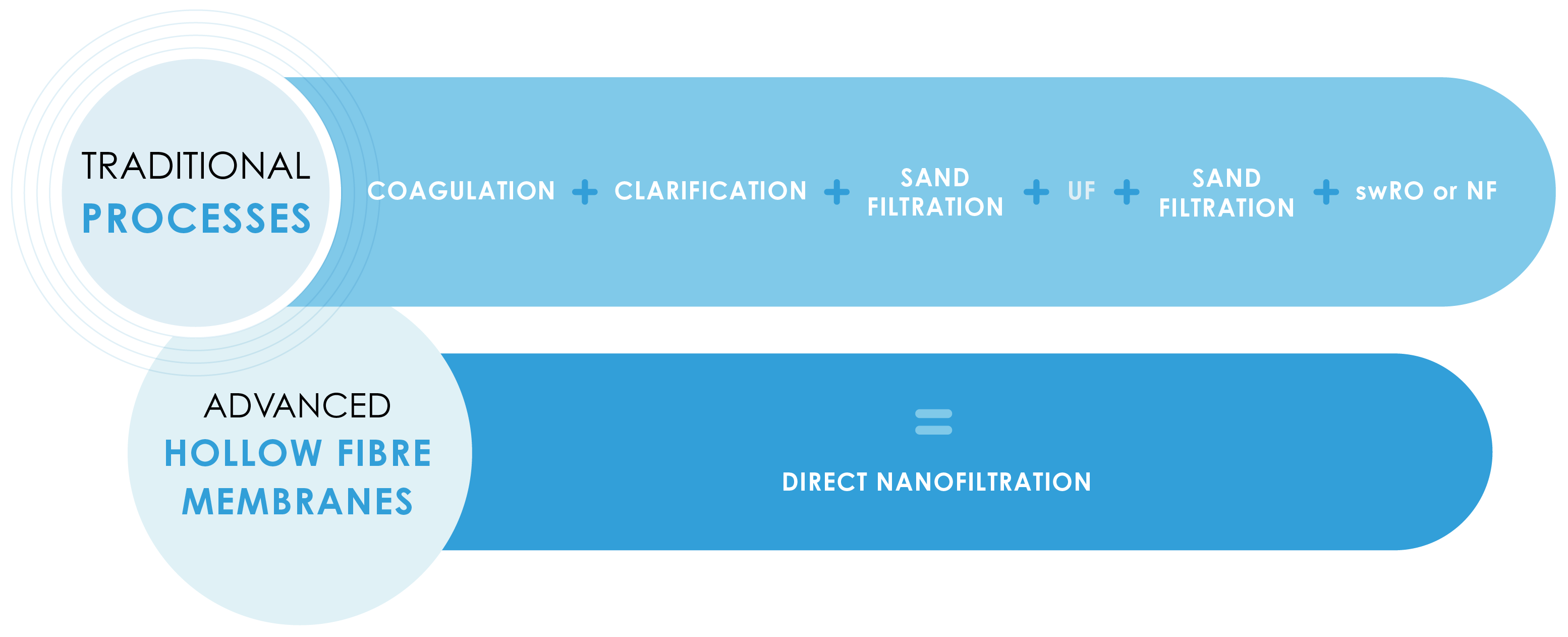

By virtue of its solids-handling capability and selective salt rejection, the SurfacePure direct nanofiltration (dNF) process can replace multiple conventional stages of surface water treatment.

This one-step approach lowers chemical demand, reduces energy use, and ensures stable water quality even under fluctuating feed conditions.

Replacing traditional multi-step surface water treatment membranes with one-step hollow fiber nanofiltration (HFNF).

Simplifying membrane filtration for surface water treatment

Conventional surface water treatment often involves coagulation, clarification, sand filtration, and ultrafiltration before final polishing. SurfacePure simplifies this process, often requiring only coarse straining before the membrane stage. The result is lower sludge production, reduced chemical handling, and a more compact installation footprint.

Scalable system design with automated control

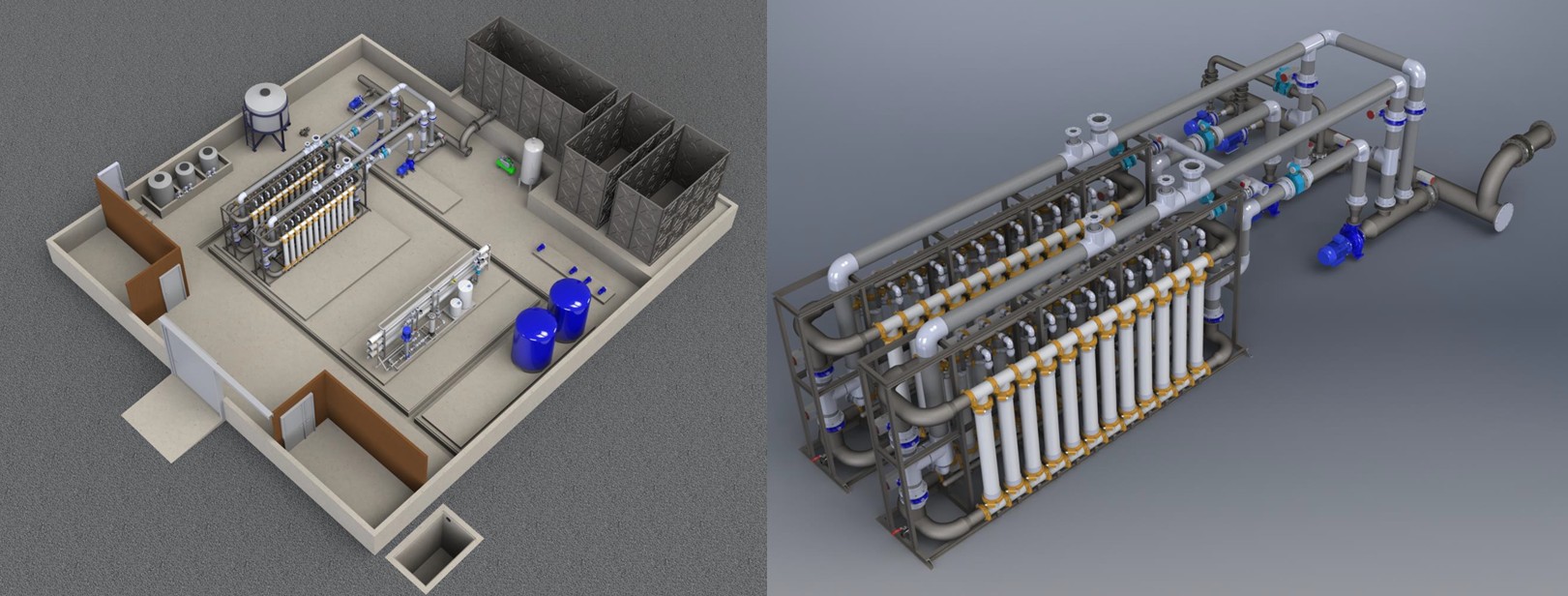

Unlike conventional treatment trains that require multiple units and stages, SurfacePure integrates everything into a compact, modular system design. Each installation is configured for the raw water source, the available footprint, and local compliance standards. This ensures reliable operation with simplified maintenance.

The design also highlights the scalability of direct nanofiltration (dNF) hollow fiber membrane technology. SurfacePure can be deployed for small community water supplies or expanded to meet the demands of large municipal applications.

Every system is supported by automated control and monitoring, including Programmable Logic Controller (PLC) / Human-Machine Interface (HMI) platforms, remote access, and integrated data logging. This makes the operation straightforward and provides operators with real-time visibility over performance and maintenance requirements.

SurfacePure system design using hollow fiber NF membranes for reliable surface water treatment.

Advanced surface water nanofiltration technology

At the core of SurfacePure are hollow fiber nanofiltration (HFNF) membranes with a molecular weight cut-off of 400–800 Da. This design enables precise removal of contaminants while maintaining stable performance.

Capabilities include:

- Natural Organic Matter (NOM) removal from surface water, including colour

- Pesticides, herbicides, and micropollutants

- PFAS, pharmaceuticals, medicines, insecticides, nanoplastics, and other emerging contaminants

- Bacteria, viruses, and pathogens

- Hardness, divalent and trivalent salts

- Taste and odour-causing compounds

Performance, compliance and sustainability in surface water nanofiltration

Surface water quality can change dramatically with rainfall and seasonal variation. SurfacePure surface water nanofiltration systems provide consistent permeate quality under these shifting conditions, ensuring compliance with drinking water standards.

Operating at lower pressure than reverse osmosis water system technology (RO), SurfacePure delivers:

- Reduced energy consumption

- Lower CO₂ footprint

- Minimal chemical requirement

- Sustainable, long-term operation

This combination of efficiency and low chemical use provides both cost and environmental sustainability benefits, supporting the delivery of pure, affordable water for communities and industries alike. SurfacePure is also a proven option for PFAS removal drinking water UK projects, addressing one of the most challenging emerging contaminants in surface water supplies.

SurfacePure represents one of the most advanced membrane water treatment UK technologies available, combining efficiency with sustainability to meet future regulatory and environmental demands.

Envirogen supports every installation with robust process performance and lifecycle expertise. Clients can also select from our PureCare water treatment plant maintenance service plans, which include the option of guaranteed rapid response available 24/7. This ensures dependable operation and long-term peace of mind for those managing critical water supplies.

Applications and use cases for surface water nanofiltration

SurfacePure is a proven choice for drinking water nanofiltration in municipal and industrial applications:

- Municipal and rural surface water treatment systems UK

- Remote and community drinking water supply

- Industrial surface water treatment membranes for food and beverage, power, and pharmaceuticals

- Emergency and temporary potable water provision

- Replacement for conventional surface water treatment trains

Related Solutions for UK Water Utilities

For projects that require DWI Regulation 31 compliance, Envirogen also offers a full range of UK-approved water filtration solutions. These include depth filter cartridges, stainless-steel housings, and containerised or skid-based systems – available to buy or rent – providing utilities and municipalities with flexible, fully compliant options for both short-term and long-term needs.

Pilot testing and validation – book a free site visit or arrange a pilot trial

Envirogen provides pilot-scale testing for nanofiltration projects to support design and performance verification. Trials can be carried out with bench-top units for sample testing or with mobile skid-mounted systems for on-site trials, giving clients the opportunity to validate performance under real conditions before moving to full-scale systems. Our hollow fiber membrane pilot plant provides a flexible approach for testing membrane technology at both the laboratory and site levels.

In addition to pilot trials, Envirogen offers a complimentary site survey to assess system requirements and ensure the right fit from the outset. This combination of pilot validation and site assessment helps reduce risk, confirm feasibility, and streamline the path to implementation.

Best for:

- Municipal and rural surface water treatment systems

- Lakes, rivers, and reservoirs as raw water sources

- Industrial facilities with surface water intake

SurfacePure Delivers:

- Safe, compliant drinking water that consistently meets standards from variable surface water sources

- Removal of Natural Organic Matter (NOM) and organic matter removal from surface water

- Colour removal surface water treatment and pesticides

- Pathogen removal drinking water and other emerging contaminants (including PFAS)

- Lower energy demand compared with reverse osmosis, reducing operating costs

- Compact skid-mounted design for rapid installation and seamless integration

- Robust compatibility with existing pre-treatment stages such as coagulation, clarification, and filtration

- Scalable range of systems, from small community installations through to large municipal plants

- Full automation, remote monitoring, and secure diagnostics

- Chlorine-resistant, backwashable membranes designed for low fouling

- Sustainable performance that supports the delivery of pure, affordable water

Choose SurfacePure if you need:

- To simplify a surface water nanofiltration train

- To reduce chemical and sludge handling

- A scalable solution for communities to large municipalities

- Reliable maintenance support and lifecycle cost certainty

FAQs

Have questions? Here are some of the most common things people ask before choosing SurfacePure. For additional technical information or if you still have questions, contact us via the form, and our team will be happy to help.

Technology and performance:

Is direct nanofiltration (dNF) the same as reverse osmosis (RO)?

No. Direct Nanofiltration (dNF) operates at lower pressure than Reverse Osmosis (RO) and selectively removes organic matter, colour, pathogens, and emerging contaminants while retaining essential minerals.

Does dNF remove PFAS and other emerging contaminants?

Yes. dNF membranes are proven to remove Per- and Polyfluoroalkyl Substances (PFAS), pharmaceuticals, insecticides, nanoplastics, and other emerging contaminants from surface water supplies.

What molecular weight cut-off (MWCO) does SurfacePure use and what does that mean for removal?

SurfacePure uses membranes with a Molecular Weight Cut-Off (MWCO) of 400-800 Daltons (Da). This allows effective removal of natural organic matter, colour, micropollutants, PFAS, and other contaminants, while essential minerals such as calcium and magnesium remain in the treated water.

Can SurfacePure handle seasonal spikes in turbidity and Natural Organic Matter (NOM)?

Yes. The system maintains stable permeate quality even when raw surface water shows large variations in turbidity and Natural Organic Matter (NOM) due to rainfall or seasonal change.

How does dNF compare to ultrafiltration (UF) and conventional coagulation/clarification for surface water?

dNF provides selective removal of organics, colour, PFAS, and micropollutants that Ultrafiltration (UF) or conventional coagulation cannot, often replacing multiple treatment steps with one stage.

Does dNF retain calcium, magnesium, and alkalinity (i.e., how much mineral retention vs RO)?

Yes. Unlike Reverse Osmosis (RO), direct Nanofiltration (dNF) is designed to allow a portion of divalent ions such as calcium and magnesium, as well as bicarbonate alkalinity, to pass through, helping preserve mineral balance and reducing the need for post-treatment remineralisation.

What recovery rates and typical flux ranges can SurfacePure achieve on surface water?

Typical recoveries are 75-85% depending on feed quality, with flux ranges of 10-20 litres per square metre per hour for surface water conditions.

How well does it remove short-chain PFAS (e.g., PFBA, PFBS) compared with long-chain PFAS?

dNF is more effective on long-chain PFAS but still achieves meaningful reductions of short-chain PFAS compared with conventional treatment.

What level of nanoplastics removal is achievable and how is it verified?

dNF removes nanoplastics down to sizes below 200 nanometres (nm), verified by challenge testing and third-party validation.

Operation and maintenance:

What are the typical silt density index (SDI)/turbidity limits and pre-filtration needs before the dNF stage?

A coarse strainer (100-200 microns) is generally sufficient; dNF membranes handle higher solids than RO, but excessive turbidity may reduce efficiency.

What pre-treatment is recommended (strainers, coagulants, media), and when is it optional?

Simple strainers are usually adequate; coagulants or clarification may only be needed for highly variable or extreme raw waters.

How often do nanofiltration membranes require backwash or clean-in-place (CIP), and which cleaning chemistries are compatible?

Backwash is automated daily to weekly; Clean-in-Place (CIP) frequency depends on fouling but is typically every few months, using standard alkaline or acid cleaners.

What is the expected membrane life on surface waters, and what factors most affect it?

With proper maintenance and pre-treatment, dNF membranes typically provide several years of reliable operation. Lifespan depends on raw water quality, fouling potential, cleaning frequency, and operating conditions, with well-maintained systems achieving extended service life compared with conventional reverse osmosis (RO) membranes.

How tolerant is the system to free chlorine and oxidants during normal operation and sanitation?

dNF membranes are chlorine-tolerant up to around 1-2 parts per million (ppm) free chlorine, unlike RO, which is quickly damaged.

What level of automation/remote monitoring is provided out of the box (alarms, data logging, remote support)?

Systems include Programmable Logic Controller (PLC) / Human-Machine Interface (HMI) control with remote access, data logging, and alarm functions, expandable with secure diagnostics.

What are the typical footprint and utilities (power, air, drains) for a standard skid or containerised unit?

A skid may be 2-3 square metres in footprint, depending on needs, with power demand similar to pumps for RO; containerised units integrate all utilities for plug-and-play deployment.

Compliance and validation:

Can you provide pilot protocols and data packages suitable for regulator or stakeholder review?

Yes, Envirogen supplies structured pilot programmes with sampling, laboratory analysis, and reporting suitable for regulator engagement.

How are pilots structured (duration, objectives, acceptance criteria), and what sample analyses are included?

Pilots typically run for days to weeks, focusing on NOM, colour, PFAS, and pathogen removal, with acceptance criteria agreed per project.

What about UK DWI Regulation 31 - how is compliance handled for projects that require it?

SurfacePure is not Reg 31 approved; for utility projects, Envirogen can offer a full range of Reg 31-approved cartridges, housings, or full systems.

Can I run a pilot first with the Hollow Fiber Membrane Pilot Plant?

Yes. Envirogen offers both bench-top and mobile pilot trials using its hollow fiber membrane pilot plant to validate performance before full-scale installation.

Commercials and deployment:

Is SurfacePure available as a containerised or skid-based system for short-term rental or seasonal demands?

Yes. SurfacePure can be supplied as a skid-mounted system or housed within a container, and both formats are available to buy or rent for temporary or seasonal requirements.

What are typical lead times, installation durations, and commissioning steps?

Timelines vary depending on project scope and site conditions. An Envirogen site survey ensures each SurfacePure system is configured for a plug-and-play fit, while our project management capabilities help deliver systems on time and within budget.

What service levels do the PureCare plans offer (response times, spares, performance guarantees)?

PureCare service plans include preventative maintenance, spares, and optional 24/7 rapid response for critical water supplies.

How are waste/concentrate streams managed and what are the expected volumes compared with conventional trains?

Concentrate is typically 15-25% of feed flow, lower than RO, reducing waste handling compared with multi-stage conventional trains.

Speak to our team of experts to discover how you could save money, increase manufacturing efficiences and reduce costs. We conduct free assessments to identify how you can improve your water treatment and process filtration systems