Sustainable water treatment solutions for the hydrogen economy

This article answers key technical questions surrounding water treatment technologies for hydrogen production, particularly in the context of electrolysis hydrogen production and emerging HAR2/HAR3 project requirements. It is intended to support project teams, consultants, and engineering partners who are specifying or validating ultrapure water systems for use in green hydrogen applications.

In this article:

- What water quality is required for hydrogen electrolysis?

- What is the role of RO + EDI in hydrogen water systems?

- Can pilot plants be used to test water treatment systems for hydrogen applications?

- How does water purity impact fuel cell production and hydrogen cooling systems?

- What is a zero liquid discharge system and why is it relevant to hydrogen?

- Which water treatment technologies are best suited to hydrogen production?

- How does this differ from conventional water treatment?

1. What water quality is required for hydrogen electrolysis?

Electrolysers require consistently high-purity water – typically below 0.1 microsiemens per centimetre (µS/cm) conductivity – to prevent scaling, fouling, and stack degradation. Poor water quality can shorten stack life, increase OPEX, and invalidate manufacturer warranties. This is why most systems include multi-stage purification combining reverse osmosis, degas membrane contactors, and electrodeionization.

2. What is the role of RO + EDI in hydrogen water systems?

Reverse osmosis (RO) technology removes the majority of dissolved salts and organics, while electrodeionization (EDI) polishes the water to ultrapure levels without chemical regeneration. This combination provides a continuous, chemical-free supply of ultrapure water and is widely used for electrolyser feed water treatment.

The H₂ HydroPro system is available in compact skid or containerised formats, providing a streamlined RO-EDI solution within our water treatment systems for green hydrogen production.

3. Can pilot plants be used to test water treatment systems for hydrogen applications?

Yes. Envirogen provides a range of pilot systems that allow project teams to test flow rate, treatment performance, and full-scale design assumptions. Pilot trials are especially useful for:

- Proving system performance on live process streams

- Supporting HAR2/HAR3 bid submissions with test data

- Demonstrating value-for-money and cost competitiveness – see how ultrapure water systems align with UK Government objectives in our dedicated article on HAR2 hydrogen project requirements

- Stress-testing different feedwater conditions

- Building full-scale OPEX models

Pilot plants are a low-risk way to validate treatment strategies before committing to full rollout – learn more about our available pilot systems on our pilot plant services page.

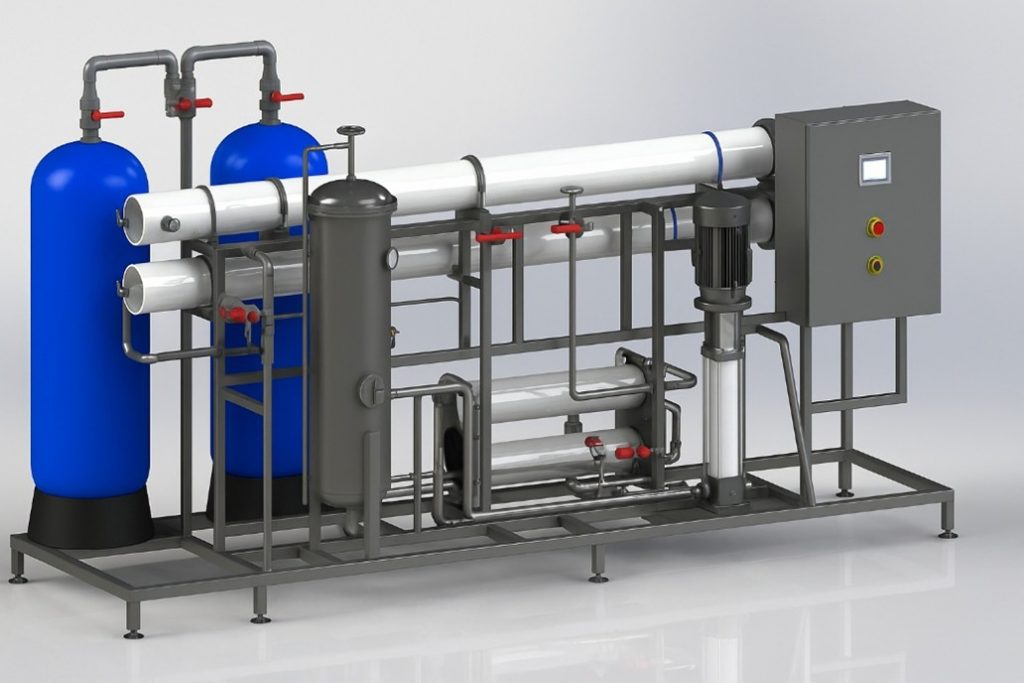

Envirogen Group water treatment system for hydrogen production

4. How does water purity impact fuel cell production and hydrogen cooling systems?

Both applications require ultrapure water to protect sensitive components. In fuel cell production, even trace contamination can damage catalyst coatings. In cooling systems, poor-quality water can lead to conductivity spikes and heat exchanger scaling. Envirogen’s systems are engineered to address both applications.

5. What is a zero liquid discharge system and why is it relevant to hydrogen?

A zero liquid discharge system (ZLD) recovers nearly all process water and eliminates liquid waste discharge. It supports sustainability objectives and is particularly relevant for projects with strict environmental permitting or those located in water-stressed regions.

6. Which water treatment technologies are best suited to hydrogen production?

Envirogen’s solutions are engineered to meet both technical and commercial demands of modern hydrogen projects. This includes systems capable of treating a wide range of source waters – from surface and ground water to municipal wastewater and seawater desalination – delivering high-quality ultrapure water using sustainable, low-footprint technologies. We also provide remote monitoring and diagnostics to support performance optimisation, proactive maintenance, and asset longevity.

Envirogen recently delivered a 400m³/hr water treatment system for green hydrogen production, demonstrating our capability to support full-scale, high-demand hydrogen infrastructure with advanced membrane technologies.

While every project is different, most designs combine:

- Reverse osmosis (RO) for primary purification

- Degas membrane contactors for CO₂ removal

- Electrodeionization (EDI) for final polishing

- Optional softening, filtration, or pre-treatment stages depending on feedwater

System configuration depends on water source, quality targets, redundancy needs, and available footprint.

7. How does this differ from conventional water treatment?

Hydrogen water purification requires far tighter control over conductivity, organics, and particulates than most industrial processes. Systems must also be chemically compatible, have minimal downtime, and support digital monitoring for remote validation and alarms.

Author: Bill Denyer, CEO UK & Europe, Envirogen Group

Bill has more than 25 years’ experience in the industrial water treatment industry. He began his career at GE in the mobile water sector and later moved into design-build-own-operate-maintain (DBOOM) systems. Bill joined Envirogen as a process and systems specialist, working extensively in brewing and soft drinks applications, and later developing hollow fibre membrane expertise across multiple regions. After transitioning to the commercial arm, he joined the executive team in 2018 and now leads Envirogen UK & Europe.

Want to see how your feedwater performs?

Get in touch for a complimentary system assessment or ask about pilot plant availability for your next HAR2/HAR3 submission.

For a free assessment to evaluate water treatment and process filtration solutions for your site, contact our team of expert engineers