The Envirogen H₂ HydroPro – a hydrogen water treatment system built for performance

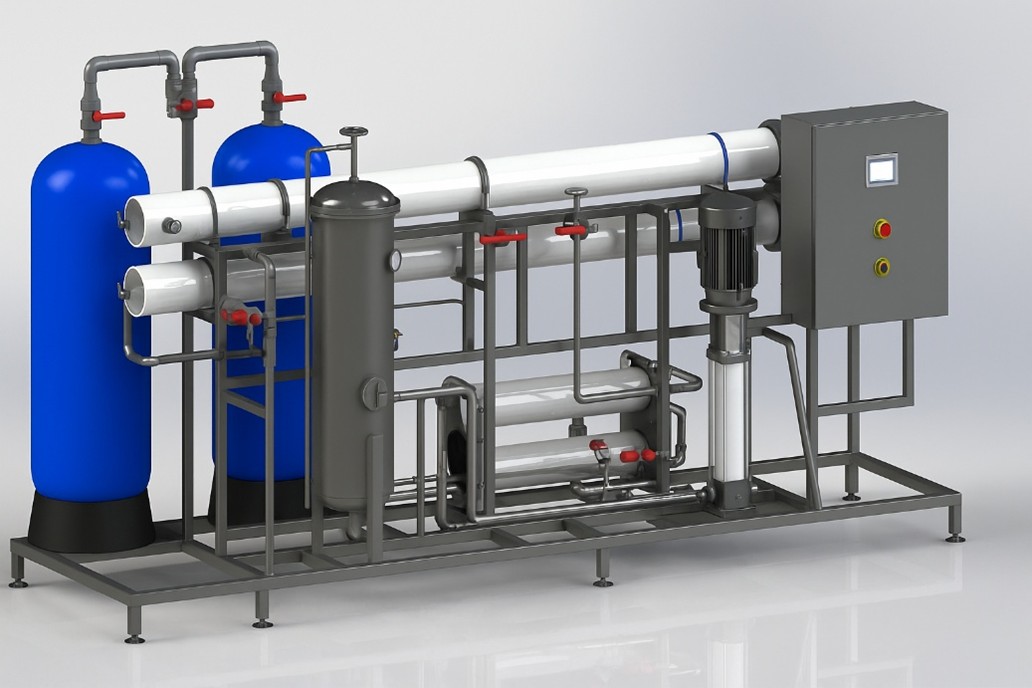

The Envirogen H₂ HydroPro is a modular hydrogen water treatment system that combines reverse osmosis, degas membrane contactors, and electrodeionisation to deliver ultrapure water for green hydrogen production. Designed for skid-mounted or containerised deployment, it ensures reliable hydrogen water purification, low operating costs, and chemical-free operation.

This multi-technology packaged solution supports flow rates up to 15 cubic meters per hour (m³/h), with larger bespoke systems available on request, while maintaining a compact footprint and scalable configuration. It is engineered to meet the rigorous quality standards of hydrogen applications – whether for continuous feedwater to electrolysers, supporting pilot trials, or ensuring high water purity for fuel cell component manufacturing. Additional polishing stages, such as ion exchange (IX), can be integrated where required to achieve the lowest conductivity and total organic carbon (TOC) levels, aligned to the hydrogen market’s most demanding purity requirements.

Envirogen also brings experience in delivering major national infrastructure projects and holistic, system-wide expertise in seawater desalination technologies, which are important considerations for coastal hydrogen projects that require high water volumes and comply with stringent regulatory requirements. Our capabilities also include advanced strategies for water reuse, water recycling, and zero liquid discharge (ZLD), critical for reducing discharge volumes and meeting the sustainability and resilience goals of modern hydrogen developments.

The H₂ HydroPro system is shown here in its standard skid-mounted layout.

Containerised formats are also available for outdoor installations.

Typical Performance

- Conductivity: less than 0.10 microsiemens per centimetre (µS/cm)

- Silica: less than 0.02 milligrams per litre (mg/l)

- Sodium: less than 0.01 milligrams per litre (mg/l)

- Total organic carbon: less than 0.20 milligrams per litre (mg/l)

Modular design for EPCs and hydrogen developers

With flexible configurations and proven technologies, H₂ HydroPro simplifies system design for EPCs, integrators, and end users building electrolyser infrastructure, fuel cell production lines, and cooling systems.

Key hydrogen applications include:

- Electrolyser feed water: Delivers the ultrapure water necessary for efficient and long-life stack operation.

- Fuel cell production: Meets the stringent water quality standards for manufacturing sensitive fuel cell components.

- Hydrogen cooling systems: Provides purified water for safe, stable cooling during hydrogen production and storage.

- Construction and commissioning: Systems are available in container or skid-based formats to support construction-phase utilities, pilot-scale validation, and water testing.

H₂ HydroPro benefits

- Hydrogen-ready design: Optimised for use as electrolyser feed water.

- Consistent ultrapure water: Maintains low conductivity and TOC levels.

- Chemical-free operation: Utilises RO and EDI for high-purity output without hazardous regeneration chemicals.

- Mixed bed polishing cylinders: Ion exchange (IX) units in lead-lag configuration ensure the highest water purity.

- Modular and scalable: Skid-mounted for rapid deployment; expandable to suit future production needs.

- Compact footprint: Ideal for hydrogen projects with limited space.

- Remote monitoring and diagnostics: Supports performance optimisation, proactive maintenance, and asset longevity.

- Lifecycle cost (LCC) optimisation: Designed for cost-effective performance over the full system lifecycle.

- Proven performance: Backed by Envirogen’s experience across regulated and high-purity sectors.

Supporting your hydrogen journey

As seen in our blog Water Treatment Systems for Green Hydrogen: Supporting HAR2 and the UK’s Emerging Hydrogen Economy, the demand for reliable, scalable hydrogen water treatment systems is growing rapidly. The H₂ HydroPro provides a practical, field-proven response to the challenges of feedwater purity, operational uptime, and environmental sustainability.

For more detailed technical Q&A, including typical conductivity targets and pilot plant options, read our companion article:

Water Treatment Technologies for Hydrogen Production – FAQs on Ultrapure Water and System Design.

For ongoing support, explore our hydrogen water treatment service provider capabilities, including planned maintenance programs designed to maximise performance and ensure long-term compliance.

H₂ HydroPro – ultrapure water system for hydrogen

Best for:

- Hydrogen projects requiring consistent water quality for electrolysers, fuel cells, and cooling systems

- Sites needing skid-mounted or containerised configurations for flexible installation

- Applications seeking chemical-free, low-OPEX solutions for long-term viability

H₂ HydroPro delivers:

- Flow rates up to 15 cubic meters per hour (m³/h) Conductivity less than 0.10 µS/cm, silica less than 0.02 mg/l, sodium less than 0.01 mg/l, TOC less than 0.20 mg/l

- Full automation, remote monitoring, and secure diagnostics

Choose H₂ HydroPro if you need:

- Reliable ultrapure water to extend electrolyser life and avoid downtime

- Pre-configured packages for fast project delivery

- Scalable systems that adapt to changing capacity requirements

- Access to maintenance support and lifecycle cost certainty

- Lead-lag configured polishing cylinders to guarantee water quality and provide peace of mind

Strategic collaboration – HS2 / Align JV case study

Envirogen has proven experience delivering modular water systems on complex, nationally significant projects.

Through strategic collaboration with Align JV – comprising Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick – Envirogen successfully delivered a custom, modular ‘plug and play’ water treatment plant to support HS2 construction.

The system reached full operational status within just six months, demonstrating how early collaboration and modular design can accelerate timelines and reduce on-site complexity for large-scale, time-sensitive hydrogen infrastructure projects. View the case study and video.